Quilts Production Lines

Yuelong provides automatic lines for the production of quilts. Our quilts production line consists of automatic opener, carding machine and ultrasonic bonder. The whole production process needs no needles, threads, adhesives, or other consumables, greatly reduce your costs and avoid the hidden danger of broken needles.

Due to no pinholes bonding, the quilt has a better warmth effect after processed. Our automatic quilt production line features high productivity with the sewing speed 5-10 times faster than traditional sewing machines.

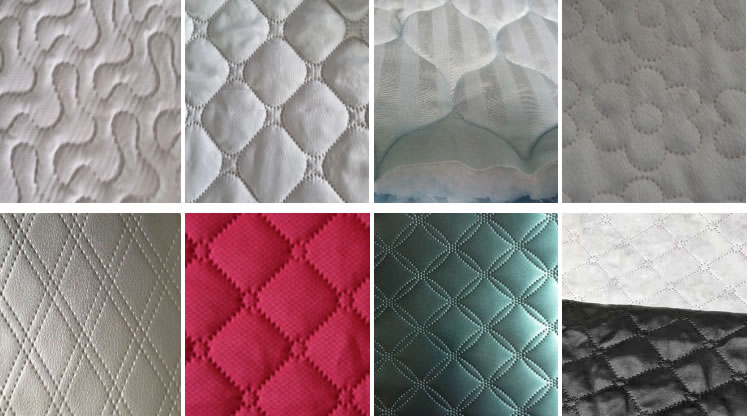

Finished Product

1.Bale Opener for cotton

Bale Opener for Cotton Opening is used to pre-open and scatter the compacted raw material, as well as transport the scattered raw material to next process. And thus cotton bale opener is always used for the front end process. The cotton bale opener manufactured by YUELONG adopts automatically feeding design for labor cost reduction.

Parameter

| Working Width: | 1200mm |

| Capacity: | 500-800kg/h |

| Roller Qty | 3 pcs |

| Machine Power | 12.1kw |

| Machine Size | 4200*1800*2550mm |

| Machine Weight | 2000kg |

Please note: We can do more than this, we can redesign the cotton bale opener according to your needs.

Before Processing

Before Processing  After Processing

After Processing

2.Carding Machine

Basic parameters of this airlay flexiloft system for cotton disentangling are listed below, contact us for more details, we can also redesign for you:

| Effective machine width | 1800~4000mm |

| Mesh-out speed | 2000~6000mm/min |

| Cylinder speed | 900~1100r/min |

| Arch model | 0.4~0.6mm |

| General power | 9~18kw |

| Size | 1800~4000mm |

| Weight | 2T-5T |

| Brand | YUELONG |

-

Before Processing

Before Processing -

After Processing

After Processing

3. Ultrasonic Bonding Machine

Our ultrasonic bonding and quilting machinery offers unique advantages for nonwovens, textiles. Only need to replace pattern rollers to achieve your desired pattern. Our ultrasonic bonder is easy to operate and increases productivity and lower maintenance cost, giving great return on your investment.

Parameter

| Model | Generator Power | Working Frequency | Capability | Working Width | Machine Size | Machine Weight |

| YL-UQ1550 | 800w*10sets | 20KHZ | 50-1200m/h | 1550mm | 5x2.0x1.8m | 1500kgs |

| YL-UQ1850 | 800w*12 sets | 20KHZ | 50-1200m/h | 1850mm | 5x2.3x1.8m | 1800kgs |

| YL-UQ2150 | 800w*14 sets | 20KHZ | 50-1200m/h | 2150m | 5x2.6x1.8m | 2100kgs |

| YL-UQ2450 | 800w*16 sets | 20KHZ | 50-1200m/h | 2450mm | 5x2.9x1.8m | 2400kgs |

| YL-UQ2750 | 800w*18 sets | 20KHZ | 50-1200m/h | 2750mm | 5x3.2x1.8m | 2700kgs |

| YL-UQ3200 | 800w*20 sets | 20KHZ | 50-1200m/h | 3200mm | 5x3.7x1.8m | 3200kgs |

Features

1)Short bonding and sewing time. Automatic ultrasonic operation, no need frequent needle change, sewing speed 5-10 times faster than traditional sewing machines.

2)Safe processing due to needle-free. Avoid the needle breakage in the material during the sewing process.

3)Eliminate unraveling, and material build-up with clear and beauty patterns.

4)No pinhole processing, good waterproof and warm effect.

5)Customize pattern rollers are available to create your desired pattern.

Linyi Yuelong Nonwoven Equipment Co., Ltd. specializes in the research, design, production, and exportation of a full line of non-woven equipment. Offering both standard and customized products, our non-woven machinery is often used for the production of mattresses, shoes, bedding and more. Using raw materials from only the most trusted names in the industry, such as Schneider, we guarantee the quality and reliability of each of our machines in meeting your exact needs.

Read MoreLinyi Yuelong Nonwoven Equipment Co., Ltd.